When it comes to ceramics, we often think of them as hard, brittle, and easily breakable. Using the definition from Kyocera's Ceramic Museum, "ceramics" also includes the ceramics, glass, cement, and refractories we use in our daily lives.

Fine ceramics, also known as advanced ceramics, primarily refers to "fine ceramics" used for industrial purposes in various industries, including electronics. Ceramic products exhibit high hardness, excellent heat resistance, corrosion resistance, and electrical insulation. Ceramics, refractories, glass, cement, and fine ceramics are representative examples. Fine ceramics, on top of these properties, possess even superior mechanical, electrical, optical, chemical, and biochemical properties, as well as enhanced functionality. Currently, fine ceramics are widely used in various fields, including semiconductors, automotive, information and communications, industrial machinery, and medical. The difference between traditional ceramics, such as ceramics, and fine ceramics lies primarily in the raw materials and manufacturing methods. Traditional ceramics are manufactured by mixing natural minerals such as mudstone, feldspar, and clay, then forming and firing them. In contrast, Fine Ceramics utilizes highly purified natural raw materials, chemically synthesized artificial materials, and compounds not found in nature. By formulating these raw materials, materials with targeted properties can be obtained. Furthermore, these formulated raw materials undergo precision-controlled processing, including molding, firing, and grinding, resulting in high-value-added products with exceptional dimensional accuracy and robust functionality.

In short, Fine Ceramics is a type of industrial ceramics that utilizes purer raw materials, more sophisticated processes, and processing methods to achieve performance and dimensional accuracy requirements.

First, the materials are collected. The weights of the aluminum oxide, zinc dioxide, and magnesium oxide required for the experiment are calculated and weighed using a balance.

Second, PVA solutions are prepared according to different material ratios.

Third, the PVA solutions prepared in steps 1 and 2 are mixed and ball-milled. This process typically takes approximately 12 hours. The ball mill speed is maintained at 900 rpm, and distilled water is used for ball milling. In the fourth step, the prepared raw materials are dehydrated and dried in a vacuum drying oven, maintaining an operating temperature of 80-90°C.

In the fifth step, granulation is performed before molding. The dried raw materials from the previous step are pressed using a hydraulic jack.

In the sixth step, the alumina product is sintered, fixed, and molded.

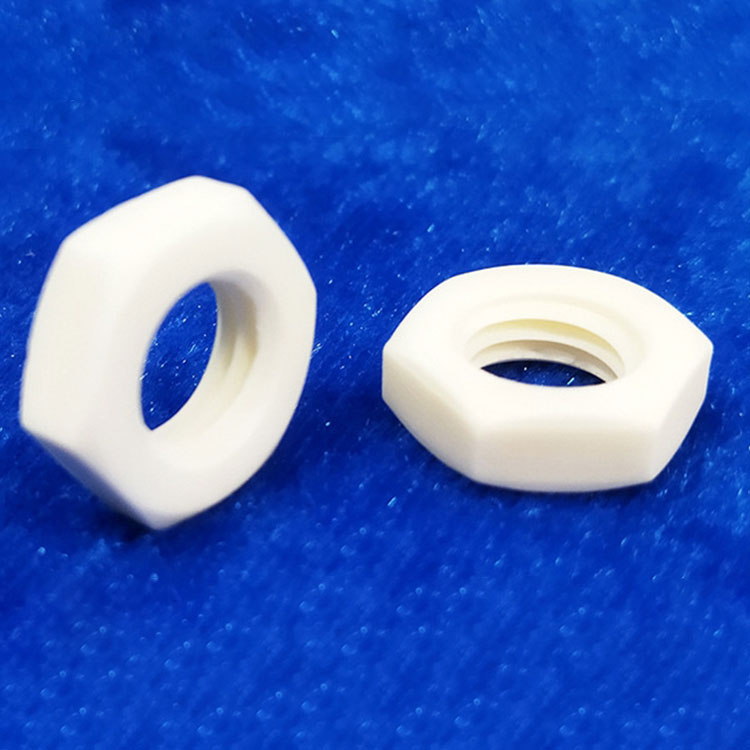

Finally, the fine ceramic product is polished and ground. This step consists of two steps: first, a grinding wheel is used to remove most of the excess large particles in the ceramic product. Then, fine sandpaper is used to finely rub and modify certain areas of the ceramic product. Finally, the entire fine ceramic product is polished, completing the production of the fine ceramic product.

Fine ceramics are high-quality ceramics manufactured using "selected or synthesized raw material powders, precisely adjusted chemical composition" and "strictly controlled manufacturing processes." Compared to traditional ceramics, they offer superior performance and are therefore widely used in various applications, including semiconductors, automobiles, and industrial machinery. Fine ceramics were once referred to as "new ceramics" or "advanced ceramics."

Fine ceramics, categorized by material, include a wide variety of materials, including alumina, zirconia, silicon carbide, and aluminum nitride. With advancements in manufacturing technology, the types of raw materials used, particle size, and firing methods are evolving, resulting in a wide range of properties. Depending on the application and purpose, the appropriate fine ceramic material is selected, the shape is determined, and the sintering process is performed to create a variety of products.

Currently, fine ceramic materials primarily include alumina, zirconia, silicon nitride, silicon carbide, and aluminum nitride.

Fine ceramics are currently used in the semiconductor industry, microwave communications, medical equipment/devices, vacuum components, piezoelectric ceramics, electronic component substrates, and other fields.

| Specification | Unit | Aluminum 99 | Aluminum 95 |

|---|---|---|---|

| Al₂O₃ Content | % | 99 | 95 |

| Density | g/cm³ | 3.85 | 3.60 |

| Water Absorption | % | 0 | 0 |

| Sintering Temperature | °C | 1690 | 1670 |

| Hardness | HV | 1700 | 1600 |

| Compressive Strength | kgf/cm² | 30000 | 25000 |

| Maximum Operating Temp | °C | 1500 | 1400 |

| Thermal Conductivity | W/(m·K) | 31 | 22 |

| Volume Resistivity | Ω·cm | >10^12 | >10^12 |

| Dielectric Constant | MHz(E) | 9.2-10.5 | 9.0-10 |

| Customization Availability | Available | Available |